Why Does My Hayward Pump and Filter Stop Filtering and Start Again Constantly

We bear the other brands, only Hayward pumps and filters have always been our flagship line.

We bear the other brands, only Hayward pumps and filters have always been our flagship line.

Reliable & durable, Hayward pumps will nonetheless likely need some type of troubleshooting at some bespeak during your relationship.

Often what appears to be a pool pump problem is really a filter problem or a valve problem, and so the first footstep is to rule out any mis-aligned valves or obstructions in the filter or pipes.

Barring problems with other pool equipment, a pool pump problem will either be an electric issue or a plumbing outcome. On the electrical side, problems can occur with the electric motor, timeclock, breaker or wires. On the plumbing side, y'all can have problems with air leaks, water leaks or but getting the water to flow properly.

Hayward Puddle Pump Electric Problems

Pump Won't Turn On

Makes No Noise: If you flip the switch and nothing happens and you hear no noise at all, check the circuit breaker by flipping information technology Off and so back On again. If you accept an mechanical fourth dimension switch or digital time clock, look into the Visual Motor Check, to meet if the tiny motor gears are turning. If there is a GFCI outlet wired into the system, check that the red button is not popped out.

Makes No Noise: If you flip the switch and nothing happens and you hear no noise at all, check the circuit breaker by flipping information technology Off and so back On again. If you accept an mechanical fourth dimension switch or digital time clock, look into the Visual Motor Check, to meet if the tiny motor gears are turning. If there is a GFCI outlet wired into the system, check that the red button is not popped out.

If power is reaching the time clock or switch, check the wires running from the switch to the pump for any signs of impairment, and inspect the connections on each stop, for loose wires or insect infestation.

If no ability is reaching the fourth dimension clock or switch, the tiny motor is expressionless, or the switch or billow is bad, or the wires from the breaker to the time clock are broken or loose.

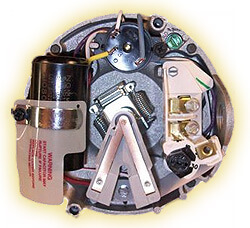

Makes Noise: If the pump motor makes a humming sound when trying to beginning, you likely have a bad start capacitor. On Hayward pumps, these are the black cylinder mounted at the rear of the motor. They are easily removed and replaced.

Before ordering a new capacitor however, be sure that the shaft is not "froze-up' with rust. To spin the shaft, disconnect power at the breaker and remove the capacitor (at 9 o'clock) and the thermal overload (at 12 o'clock) so that y'all can slip a vii/xvi" wrench onto the slotted shaft.

Before ordering a new capacitor however, be sure that the shaft is not "froze-up' with rust. To spin the shaft, disconnect power at the breaker and remove the capacitor (at 9 o'clock) and the thermal overload (at 12 o'clock) so that y'all can slip a vii/xvi" wrench onto the slotted shaft.

Use the wrench to wiggle the shaft through several revolutions to break any rust that has formed between the stator and rotor and complimentary up the shaft. Carefully re-secure the capacitor and thermal overload switch.

If the pump won't start or run, check these things

- If the motor does not turn on, cheque the billow and timeclock switches.

- If the motor hums merely does not start, bank check that the shaft is free-spinning, then check the capacitor

- If the motor makes no dissonance at all, check the wiring and terminal connections.

- If the motor won't come up to full speed, bank check the incoming voltage with a multi-meter.

- If the motor is sparking and smoking, check the terminal wiring diagram for 230V.

- If the motor is loud, remove from pump and test briefly. If still loud, supervene upon bearings/seal.

Pump is Shutting Off by Itself

Not a good sign commonly. If it turns dorsum on after xv minutes, it likely has been overheating. Provide shade if necessary, and make sure that air is circulating freely under all parts of the motor, and that the motor vents are open up. Rake effectually the expanse to remove any leaves or mulch, and trim dorsum overgrown bushes and overgrown copse that may block cooling breezes.

Other causes of a pump shutting itself off include loose or cleaved wires or wrong voltage, more than than 10% more or less of the rated input voltage. In most cases however, a motor that is over-heating tends to be defective beyond repair, when caused by an internal short across the motor windings.

Pump is Smoking or Sparking

Whoa, shut the pump off chop-chop. Smoking pump motors are usually caused by connecting 230V to a motor wired to receive simply 115V. Check the motor diagram for the Low Voltage / Loftier Voltage wiring diagram. An incorrectly installed shaft seal can also produce friction smoke, and a blown capacitor volition throw off a lot of smoke, following the small explosion.

Whoa, shut the pump off chop-chop. Smoking pump motors are usually caused by connecting 230V to a motor wired to receive simply 115V. Check the motor diagram for the Low Voltage / Loftier Voltage wiring diagram. An incorrectly installed shaft seal can also produce friction smoke, and a blown capacitor volition throw off a lot of smoke, following the small explosion.

Sparking motors tin can be acquired by loose wire connections or two wires or concluding connections touching each other, which is usually hands fixed. Sparking tin can likewise come directly from a curt in the windings of the motor, which usually means the motor is about the end.

Pump Trips the Breaker

When the breaker trips when trying to turn on the pump, most likely the motor shaft is frozen, the impeller is stuck, or the capacitor has blown. In some cases, information technology tin be a bad breaker, especially one that is used often to plough the pump on and off.

If the billow trips while the pump is running, the pump is likely drawing more amperage or voltage than the breaker rating. This could be caused by wrong voltage or from clogged or restricted pipes, valves or impeller. It could also be merely a bad breaker.

If the breaker trips when turning on pump, cheque:

- Look for wire problems in back of motor – crimped, split, touching.

- Check the motor shaft, the impeller should turn freely by hand.

- Shut off power at breaker and tighten all wire connections.

- Check timer clock or switch for burnt terminals or wires.

- Check capacitor for …capacitance or resistance with an Ohm meter.

- If breaker nevertheless trips, replace the billow; they become bad eventually.

Pump simply Runs for 5 seconds

If your Hayward pump runs for only 5 seconds and shuts off, check the incoming voltage. Most inground Hayward pumps are shipped to accept 230V, and if yous simply give it 115V, it can't get upwards to speed.

Many inground pumps are have 'reversible voltage', and tin be switched from 230V to 115V by turning a tab or by switching a few wires on the terminal board.

If the motor turns on and off, cheque these things:

- Clear away mulch and leaves from effectually the motor air vents.

- Close off power at billow and tighten all wire connections.

- Check that motor wires are non broken, wet, or touching each other.

- If it continues to overheat and close off, replace the motor.

Hayward Pool Pump Plumbing Problems

Pump is Leaking Water

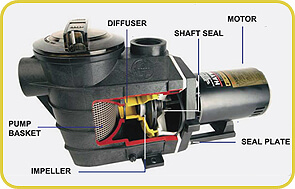

A pump that is leaking h2o is usually a bad shaft seal or a loose piping connected into the tiptop of the pump. Leaks tin also come from loose bleed plugs or loose on bolts on the seal plate, connecting the motor to the pump.

If the water is running down between the pump and motor, determine if it's dripping out of the plumbing plumbing equipment on top or the shaft seal on the lesser.

If you accept simply replaced the seal, it may have been placed on the impeller backwards, or the seal plate gasket is out of position, or the diffuser is misaligned and the seal plate is not sealing upwardly against the pump body.

Pump Basket has Air Within

![]() The opposite of a h2o leak, and air leak pulls h2o into the pump, and is ever located in front of the pump impeller.

The opposite of a h2o leak, and air leak pulls h2o into the pump, and is ever located in front of the pump impeller.

Mutual air leak sources are a loose or croaky pump hat or dirty chapeau o-ring, or just a loose lid (they must exist tight!). Nearly often the cause is the threaded plumbing equipment coming into the pump. Pool putty tin make a semi-permanent repair, or the plumbing equipment can be cut out and replaced.

Other causes of air leaking into the pump is from leaky valves in forepart of the pump, low water level in the puddle, or a skimmer weir stuck in the up position.

Pump is non Pumping Water

If the pump is non pumping water at all, check that all suction and return valves are open, and the pump chapeau is on tight, with the lid o-ring in place. Lubricating the lid o-band regularly volition assist amend the seal. Cheque that the drain plugs are tightly inserted with Teflon tape, and that the pump handbasket is inserted in the proper mode, and is sitting all the way downward.

If the pump has lost prime completely, fill a bucket with water or bring over a garden hose and re-prime the pump manually by filling up the pump. If the pump won't catch after a several attempts to make full with water, check for an air leak (see above) on the suction side of the pump, an obstruction in the line, or low water level.

If the pump has lost prime completely, fill a bucket with water or bring over a garden hose and re-prime the pump manually by filling up the pump. If the pump won't catch after a several attempts to make full with water, check for an air leak (see above) on the suction side of the pump, an obstruction in the line, or low water level.

If you only pulled the pump to check the impeller or replaced a shaft seal, make sure the seal is installed correctly and that the diffuser and diffuser gaskets are seated firmly.

If the pump won't pump water fully, check that:

- Suction side valves (skimmers, principal drain) are open.

- Older suction side valves tin can leak air (pull air in) through stem or lid.

- Pump chapeau o-ring is a good fit, in good condition, and lubricated.

- Pump lid cover is Tight (actually tight).

- Impeller is not chock-full with small-scale droppings.

- Check that pump basket is not cleaved or misaligned.

- Pool Filter is make clean, and filter valve is on Filter or Recirculate.

- Return side valves (later on the filter) are open.

- Pump does non drip h2o from plugs or seal when pump is off.

- Test entrance pipage fitting (threads into forepart of pump) for Air leakage.

- Utilise shaving cream or soapy water to see if it sucks into pump.

- Look for h2o spray back or dripping when pump shuts off.

- Supercede the fitting, with lots of thread sealant, or utilise pool putty.

- Bank check the skimmers, to be sure that water flow is not blocked.

Pump Catamenia Charge per unit is Low

When the filter pressure is high, the filter is dirty ~ and when the filter pressure is low, the basket(south) are dirty. Lower than normal force per unit area on the filter corresponds with lower than normal flow rates.

Check the pump impeller by removing the pump basket and reaching through the hole to experience for any debris or rocks stuck inside the impeller. If yous feel annihilation unusual, remove the bolts to pull the motor out for a good cleaning of the impeller.

Check the pump impeller by removing the pump basket and reaching through the hole to experience for any debris or rocks stuck inside the impeller. If yous feel annihilation unusual, remove the bolts to pull the motor out for a good cleaning of the impeller.

An air leak (encounter to a higher place) will as well reduce water flow rates, as air is drawn in to the pump, and a dirty pool filter or baskets can clog upwardly the works, and reduce the flow charge per unit. In some cases, it can be a clog in the skimmer line, or even a partially collapsed suction line that is to blame.

Pump is Loud or Noisy

A loud or noisy pump can be either a plumbing or electrical problem. If the pump sounds like it'southward gargling rocks, or at that place is heavy vibration noise, it may be cavitating, a term that means it's starved for water. It'south either too powerful for the incoming plumbing, or too many suction lines are closed, or the skimmers are chock-full.

A loud or noisy pump can be either a plumbing or electrical problem. If the pump sounds like it'southward gargling rocks, or at that place is heavy vibration noise, it may be cavitating, a term that means it's starved for water. It'south either too powerful for the incoming plumbing, or too many suction lines are closed, or the skimmers are chock-full.

A motor with a more than loftier pitched squeal or screech is usually in need of shaft bearings. There are two sealed bearings inside pool pump motors. They tin exist replaced, only unless the motor is quite new, nigh pool owners will replace the entire motor.

That's all Folks! If these quick tips didn't solve your problem, feel free to call our pool tech supporters at 1-800-288-7946 for more than Hayward puddle pump troubleshooting.

That's all Folks! If these quick tips didn't solve your problem, feel free to call our pool tech supporters at 1-800-288-7946 for more than Hayward puddle pump troubleshooting.

And if you are in need of 18-carat Hayward Replacement parts, we have Hayward pump parts and motor parts stocked in 12 warehouses for fast delivery with same day shipment!

Davy Merino

InTheSwim Weblog Editor

FEATURED PRODUCTS:

Source: https://blog.intheswim.com/hayward-pool-pump-troubleshooting/

0 Response to "Why Does My Hayward Pump and Filter Stop Filtering and Start Again Constantly"

Post a Comment